Structuring of the Consulting Performance in Moduls according to our staff's specialists

1. Modul: Stone Feasibility: Analyzing natural Stone regarding the necessary Processing Procedures

- Expertise regarding the best processing method regarding a specific stone

- Listing of the possible semi finished and finished products

2. Modul: Production Know How - Potential Production Capacity of different Machinery: Determination according to the specific stone and block shapes / dimensions

- Block Cutter products - 650 mm Finishing Lines

- Gang Saw products - 2.000 mm or larger Finishing Lines

- Potential Productivity concerning the Finished product groups

3. Modul: Economic - administrative Feasibility Study of the Project

- Plant aviation and long term development projection

- Tiles Production Plant long term development projection

- Slabs Production Plant long term development projection

- Final Evaluation

4. Modul: Logistics and Expansion

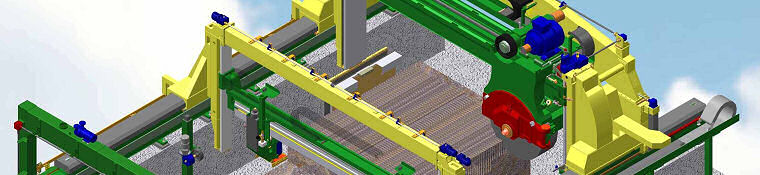

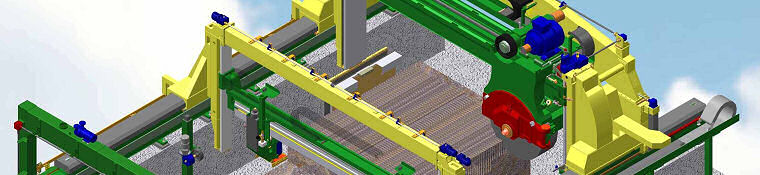

- Lay Out (machinery positioning - blocks yard - semi finished goods - finished goods - water depuration plant, generator, compressor)

- Expansion Plans and Possibilities

- Indoor Processing Plant details

5. Modul: Machinery Requirement List according to the best Processing Technique

- Machinery type specification

- Machinery productivity specification (time - precision)

- Machinery components specification

6. Modul: Consumables Requirement List

- Chemical treatments procedures - evaluation

- Polishing Stones evaluation

- Diamond Discs evaluation

- Others for: brushing, honing, bush hammering, flaming, satin look

7. Modul: Production Organisation and Quality Assurance

- Organ gram of the factory - company

- Production Procedures Manual

- Quality Handbook

- Specialized Software for 'Modern Stone Factory Management'

8. Modul: Services for already existing Stone Processing Plants

- Determination of the present production strength and weakness features

- Development of an activity list for improvement under the given production conditions

- Development - Expansion - Automation - Rationalization of a quality production